Effluent Treatment Plant manufacturers in India

The Effluent Treatment Plant ( ETP ) is a type of wastewater treatment plant that is used to treat wastewater before it is discharged back into the environment.

They are used to treat sewage water by removing organic matter and inorganic matter like salts, minerals, metals and other contaminants that may be present in the water.

An ETP typically consists of a series of tanks or ponds in which the wastewater flows from one to the next. These tanks are filled with different types of bacteria and plants that act as natural filters for the water, removing harmful substances like heavy metals, pesticides, nitrates and phosphates.

Unicare is a Global Leader In The Manufacturing of ETP Plants in India

Importance of Effluent Treatment Plant

The Benefits of ETP plants are:

1) They help in the removal of contaminants from water which can be hazardous for humans and the environment.

2) They are highly efficient in removing organic matter, suspended solids and nitrogen compounds from water.

3) They also help in the removal of heavy metals like lead, copper, zinc etc.

The Effluent Treatment Plant is a facility which processes wastewater from industries and households. It removes the contaminants from wastewater by using the process of biological treatment, chemical treatment and physical treatment.

It is a state-of-the-art plant which has been designed to meet the needs of today’s society. The plant has been constructed in compliance with all environmental norms and regulations.

Effluent Treatment Plant Working Process

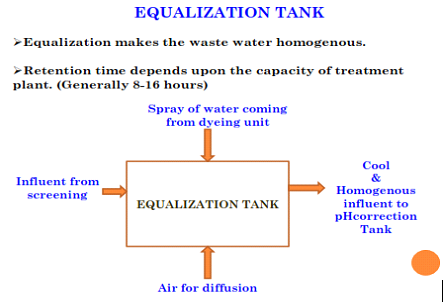

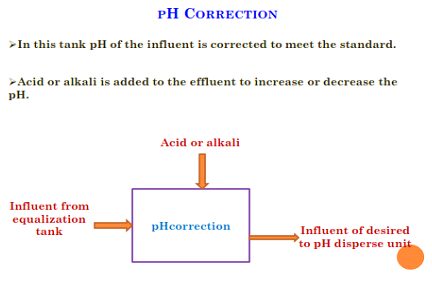

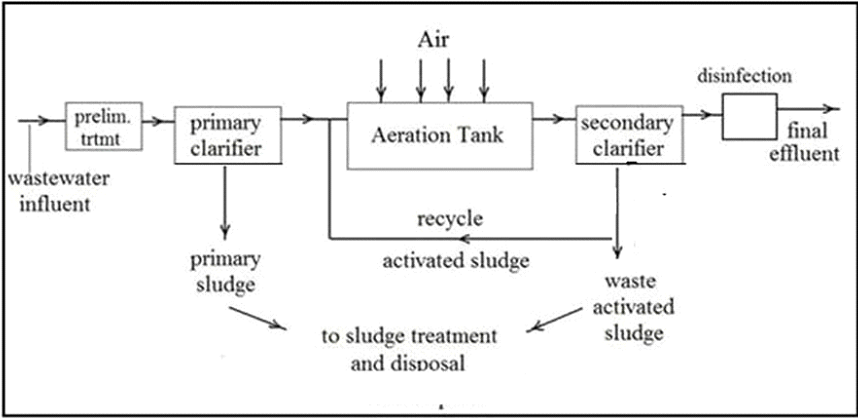

The primary function of an effluent treatment plant is to remove pollutants from wastewater. The process can be classified into four stages: pre-treatment, primary treatment, secondary treatment and tertiary treatment.

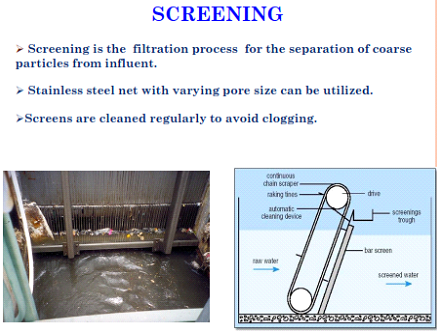

Preliminary | Removal of visible larger solids that may damage equipment or result in operational problems. |

Primary | Remove floating debris and solids or settleable materials such as suspended solids and organic matter from the water. |

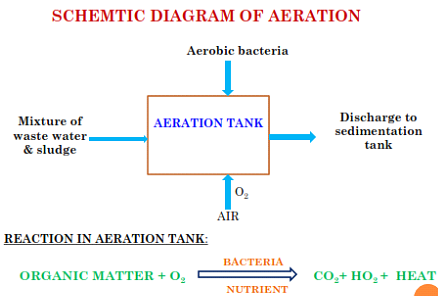

Secondary | The water is aerated to release dissolved gases such as hydrogen sulfide. Helps in the Removal of biodegradable organic matter and suspended solids. |

Tertiary | Treatment involves the use of chemicals to remove remaining nutrients. Helps in the Removal of residual suspended solids / dissolved solids. |

Applicable areas of ETP

- Food and processing industries

- Pharmaceutical industry

- Tannery & Paper industries

- Textile and dye industry

- Dairy and Beverage industries

- Paint Industry

- Chemical Industries, etc.

Why choose Unicare?

There are many reasons why you should choose Unicare technologies for your next project, Our plants are designed with your needs in mind – We offer customized solutions – We have a wide range of products at competitive prices.

Safe and sustainable solutions

We’re committed to providing safe and sustainable solutions that meet the needs of our customers. Our products are designed to be ecologically friendly, without compromising on performance.

Expertise in every field

We’re experts in every field, from water treatment and recycling to sludge disposal and sewage treatment. We’ve been designing, building, and maintaining ETP plants for over 20+ years- so you can rely on us to get the job done.

We're always here for you

Unicare is committed to providing the best customer service possible. We have a dedicated customer service team that’s happy to help with any questions or concerns you may have.

We make the world’s best plants. To find out more about our product & services, please visit our website or contact us today!

FAQ:

What is an ETP plant?

An ETP plant or Enhanced Thermal Processor is an environmentally friendly solution to the problem of how to deal with produced water from oil and gas wells. It is designed to reduce the amount of produced water that has to be disposed of as wastewater.

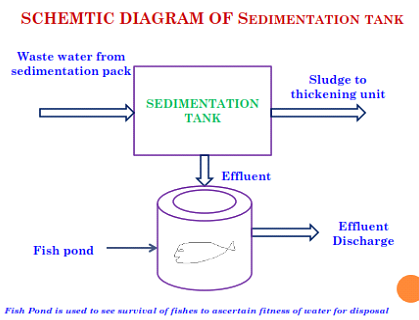

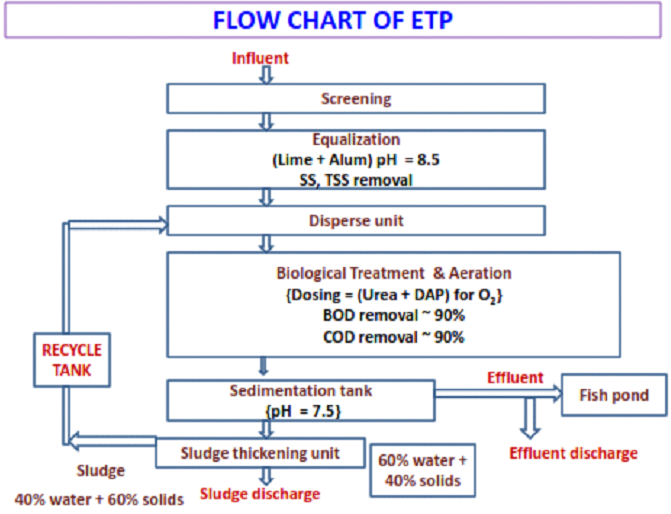

Flow chart for ETP

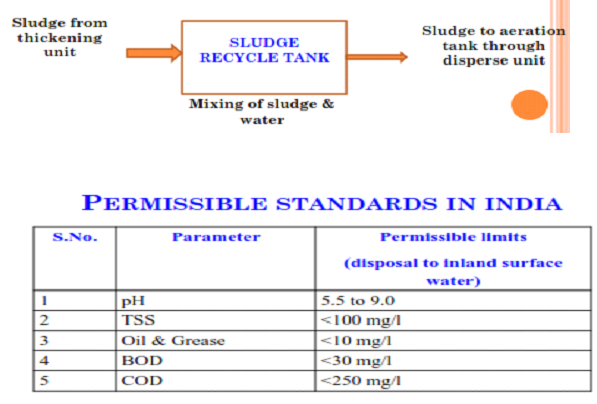

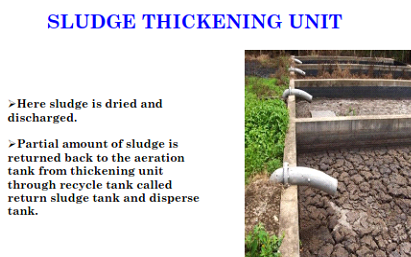

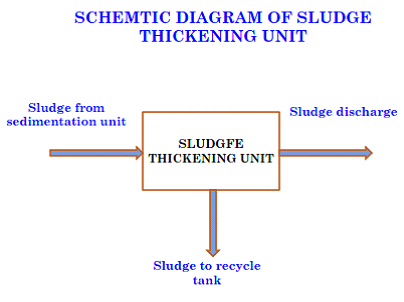

RETURN SLUDGE TANK

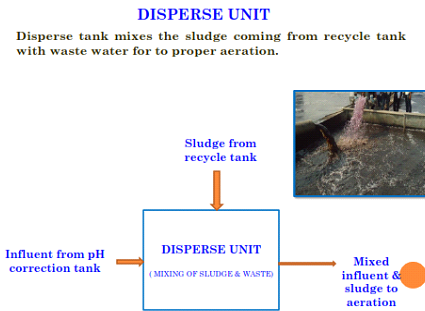

- The function of the return tank or recycle tank is to mix water with

sludge - This mixture is then passed to the aeration tank through dispersing

tank.

ADVANTAGE OF RECYCLING SLUDGE TO AERATION TANK

- Sludge is again oxidized to minimize the pollution from sludge.

- Alive bacteria of sludge is again used in aeration to utilize this

bacteria.