Effluent Treatment Plant manufacturer in India

Industrial effluent treatment plant manufacturers in Pune, India are specialized in providing effective and efficient solutions for the treatment of effluent water generated by various industries. These plants are designed to remove harmful pollutants and contaminants from the wastewater and ensure that the treated water meets the standards set by regulatory authorities.

With their expertise in designing and manufacturing customized effluent treatment plants, these manufacturers in Pune cater to a wide range of industries, including chemical, pharmaceutical, food and beverage, and textile industries. They offer a comprehensive range of services, including plant installation, commissioning, maintenance, and repair.

Their effluent treatment plants are equipped with advanced technologies such as membrane filtration, reverse osmosis, and activated sludge process, which ensures high-quality treated water output. These plants are also designed to be energy-efficient

Unicare Is A Leading Industrial Water Treatment Plant Manufacturer In India.

As we all know industrial wastewater contains very toxic chemicals which can harm the environment, It

causes a significant effect on human health. It is very important for Industries to release water after

proper treatment and must adopt sustainable methods of storing it. Unicare Industrial effluent treatment plant manufacturers in Pune, India or industrial

water treatment plants in India, which are used by many industries – including mining, food processing,

Metal production, and Oil and gas production. These plants are customized to meet various types of

Industries’ needs.

What is Industrial Water Treatment Plant?

Reasons to Use Industrial Wastewater Treatment Plants

.Industrial wastewater is considered to be the most challenging of all wastewater and it is not just a

problem for industries. It poses a major threat to human health and the environment.

Industrial wastewater treatment is an important part of any industrial wastewater management plan

and it needs to be done with utmost efficiency.

Industrial wastewater treatment is a process in which contaminants and pollutants are removed from

the water. Wastewater treatment is done to meet the standards of water quality that are set by

regulatory agencies. These standards are usually based on the intended use of the treated water.

There are many reasons why industrial wastewater treatment is used, including:

– To remove contaminants and pollutants

– To prevent contamination of drinking water

– To provide a safe work environment for employees

Types of Industrial Water Treatment Plants Available

There are different types of industrial water treatment plants available in the market, which help

industries to reuse wastewater after treatment. Also, a combination of systems is put in place

dependent on the water issue.

If you are looking for industrial wastewater treatments, here are some options that you can consider:

– Chemical treatment

– Biological treatment

– Physical treatment

– Thermal treatment

– Membrane filtration

– Reverse osmosis

How Industrial Water Treatment Plants Works?

The process of treating industrial wastewater is complex and requires a number of different stages.

Steps that are taken to remove pollutants from wastewater, and it is designed to meet the requirements

of the Clean Water Act. This process ensures that any water that is released into the environment meets

all standards for water quality.

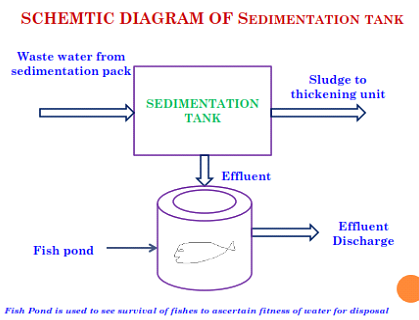

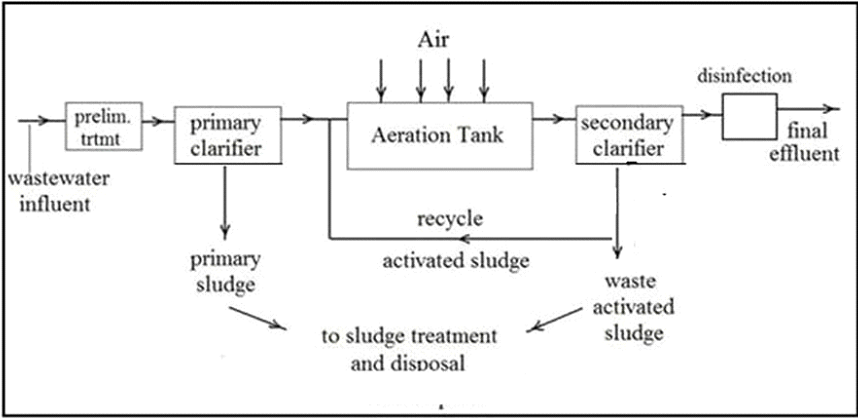

The first type of industrial wastewater treatment plant is a primary treatment plant. It removes solids,

fats and oils, suspended solids, and floating materials from the water through sedimentation or

chemical precipitation. This leaves behind a concentrated sludge that needs to be dewatered before

being discharged.

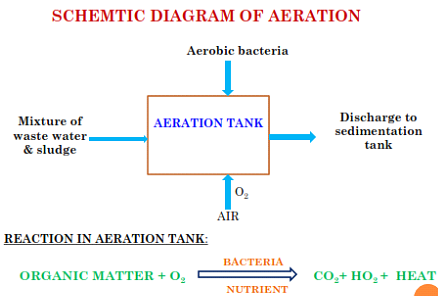

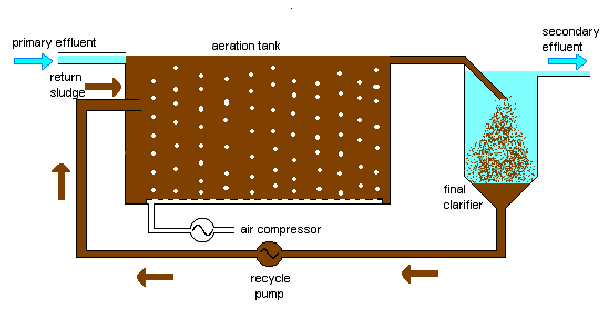

The second type of industrial wastewater treatment plant is an activated sludge process which also

removes organic matter by biological decomposition in aerated tanks with added chemicals like chlorine

or ozone to destroy pathogens. Anaerobic digestion may also be used as an additional step in this

process where bacteria breaks down organic matter in the absence of oxygen.

The third type of industrial wastewater treatment plant is a secondary treatment plant, which removes

more suspended particles.

Top 5 Benefits of Industrial Water Treatment

There are many reasons why this is important. Some of these reasons include:

1. Helps protect workers, who are at risk of exposure to hazardous materials that could cause

illness or injury

2. Reduces risk of pollution and contamination into local water supplies and ecosystems, which can

lead to diseases or other health problems

3. Prevents damage to natural habitats through pollution -Protects aquatic life by reducing toxic

chemicals in waterways

4. The best treatment for protecting the Environment.

5. Boost productivity and strengthen the economy.

If you are looking for the best way to take care of your industrial needs, look no further than Unicare

industrial water treatment plant. We specialize in designing and manufacturing industrial water

treatment plant manufacturers in India that meet your exact requirements – whether you need to treat

a large amount of water or just a small amount.

We have a range of plants and solutions that are tailored to meet any industry demands. We are a

team of engineers who have years of experience in the field. Our team will help you make an informed

decision on what water treatment system is best for you, ensuring that you get the most out of your

purchase!

ETP (Effluent Treatment Plant) is a process designed for treating industrial wastewater for its reuse or safe disposal in the environment.

- Influent: Untreated industrial wastewater.

- Effluent: Treated industrial wastewater.

- Sludge: Solid part separated from wastewater by ETP.

The design and size of the ETP depend upon:

- Quantity and quality of the industry’s discharge effluent.

- Land availability.

- Monetary considerations for construction, operation & maintenance.

Area dimension depends on:

Quality of wastewater to be treated,

Flow rate

Type of biological treatment to be used.

Treatment levels:

Preliminary

Primary

Secondary

Tertiary (or advanced)

Treatment mechanisms:

Physical

Chemical

Biological

Preliminary Treatment level Purpose:

Physical separation of large-sized contaminants such as fabric, plastics, wood logs, paper, and so on. At the Preliminary level, common physical unit operations include:

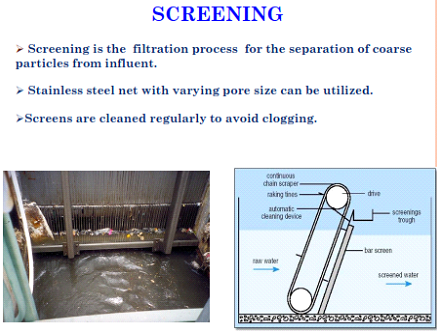

Screening: A screen with uniformly sized apertures is used to remove big particles such as plastics, fabric, and so on. In most cases, a maximum of 10mm is employed.

Sedimentation is a physical water treatment method that removes suspended materials from water using gravity.

Clarification is the process of separating particulates from fluids.

Purpose: Removal of floating and settleable materials such as suspended solids and organic matter.

Methods: Both physical and chemical methods are used in this treatment level.

- Chemical unit processes are always employed with physical activities, but they can also be utilised with biological treatment procedures.

Chemical procedures involve the addition of chemicals to wastewater to alter its quality.

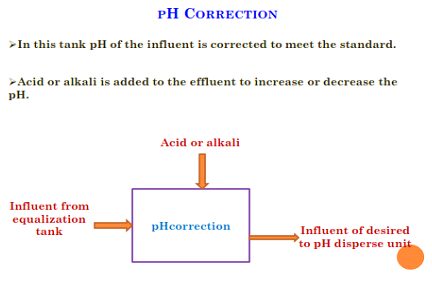

Example: pH control, coagulation, chemical precipitation and oxidation.

Chemical coagulation and Flocculation:

- Coagulation is the process of gathering minute solid particles scattered in a liquid into a bigger bulk.

- Chemical coagulants, such as Al2(SO4)3, often known as alum, or Fe2(SO4)3, are added to wastewater to strengthen the attraction of tiny particles, causing them to clump together and create bigger particles known as flocs.

- A chemical flocculent (often a polyelectrolyte) improves the flocculation process by bringing particles together to create bigger flocs that settle out faster.

- Gentle mixing encourages the particles to collide, which aids flocculation.

Secondary Treatment Level

Methods: Biological and chemical processes are involved in this level.

Biological unit process

- Organic and inorganic substances are removed or reduced in concentration..

- Biological therapy can take numerous forms, but they are all based on microorganisms, mostly bacteria.

Aerobic Processes

- In the presence of air, aerobic treatment procedures take happen (oxygen).

Microorganisms (aerobes) that use molecular/free oxygen to absorb organic pollutants, converting them to carbon dioxide, water, and biomass are used.

Tertiary / Advanced Treatment

Purpose: Final cleaning procedure to raise the quality of wastewater before it is utilised again, recycled, or released into the environment.

Mechanism: Removes any leftover inorganic chemicals, including phosphorus and nitrogen. At this step, bacteria, viruses, and parasites that are hazardous to public health are also eliminated.

Methods:

- Alum: Used to aid in further phosphorus particle removal and amalgamate the remaining solids for straightforward filter removal.

- Chlorine: By removing bacteria, viruses, and parasites from treated wastewater, a chlorine contact tank disinfects secondary treated wastewater.

- Just before it is released, sodium bisulfate is added to eliminate any remaining chlorine..

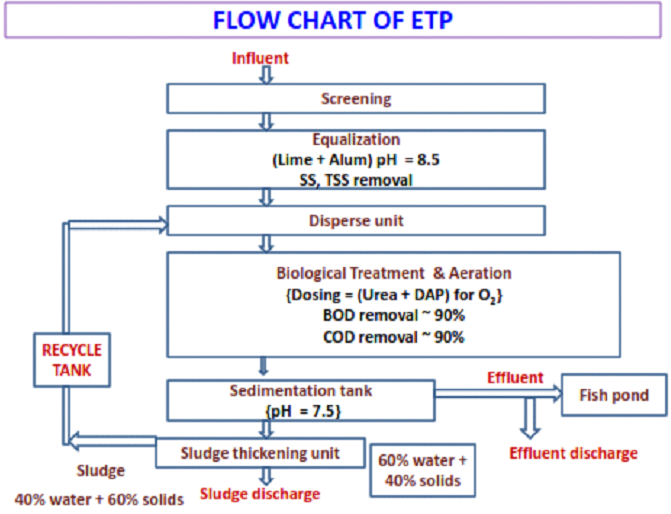

Flow chart for ETP

ETP Plant Operation

- Screen chamber:

Remove relatively large solids to avoid abrasion of mechanical equipments and clogging of hydraulic system. - Collection tank:

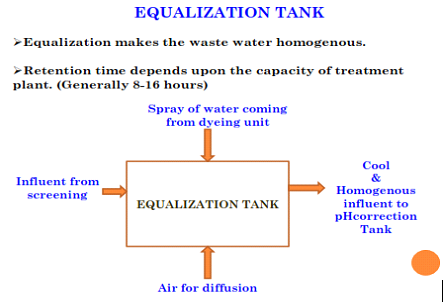

The collection tank collects the effluent water from the screening chamber, stores and then pumps it to the equalization tank. - Equalization tank:

The effluents do not have similar concentrations at all the time; the pH will vary time to time.

Effluents are stored from 8 to 12 hours in the equalization tank resulting in a homogenous mixing of effluents and helping in neutralization.

It eliminates shock loading on the subsequent treatment system.

Continuous mixing also eliminates settling of solids within the equalization tank.

Reduces SS, TSS. - Flash mixer:

Coagulants were added to the effluents:

1. Lime: (800-1000 ppm) To correct the pH upto 8-9

2. Alum: (200-300 ppm) To remove colour

3. Poly electrolyte: (0.2 ppm) To settle the suspended matters & reduce SS, TSS.

The addition of the above chemicals by efficient rapid mixing facilitates

homogeneous combination of flocculates to produce microflocs. - Clarriflocculator:

In the clarriflocculator the water is circulated continuously by the stirrer.

Overflowed water is taken out to the aeration tank.

The solid particles are settled down, and collected separately and dried; this

reduces SS, TSS.

Flocculation provides slow mixing that leads to the formation of macro flocs,

which then settles out in the clarifier zone.

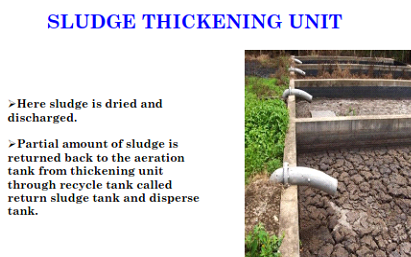

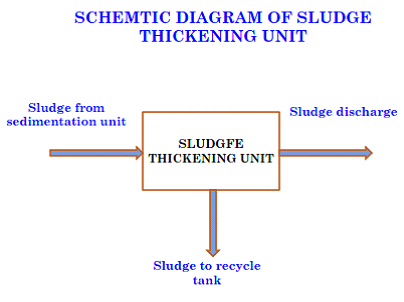

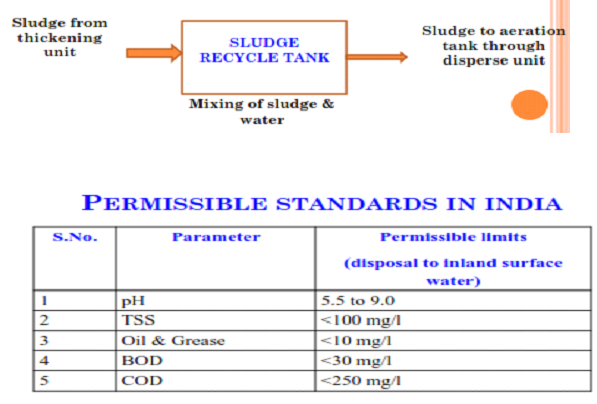

The settled solids i.e. primary sludge are pumped into sludge drying beds. - Sludge thickener:

The inlet water consists of 60% water + 40% solids.

The effluent is passed through the centrifuge.

Due to centrifugal action, the solids and liquids are

separated.

The sludge thickener reduces the water content in the

effluent to 40% water + 60% solids.

The effluent is then reprocessed and the sludge collected

at the bottom.

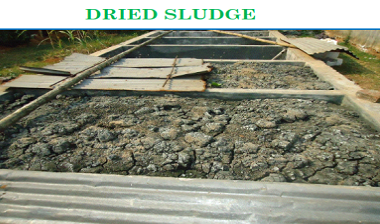

- Drying beds: Primary and secondary sludge is dried on the drying beds.

RETURN SLUDGE TANK

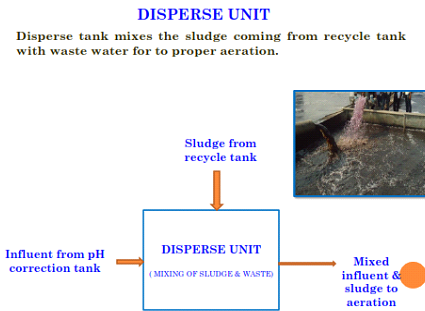

- The return tank or recycling tank’s role is to combine water and sludge.

- This combination is then transferred through the dispersing tank to the aeration tank.

ADVANTAGE OF RECYCLING SLUDGE TO AERATION TANK

- To reduce sludge contamination, sludge is oxidised once more.

- To employ these bacterium, alive sludge bacteria are used in aeration once again.

Portable RO for Hemodialysis:

Unicare provides a variety of portable RO systems for home dialysis. We provide a broad assortment of portable dialysis devices intended to give high-quality, filtered water when and when patients require it, whether at home or in a clinical environment.

Our reverse osmosis (RO) machines are built to deliver consistent output and comprehensive monitoring capabilities for easy administration and operation. All systems are in accordance with current AAMI guidelines and CMS criteria, and we are always educating our clients and staff on new needs.

Benefits:

The machine’s all-inclusive cabinet design and onboard carbon antiscalant eliminate the need for a water softener, and it includes extra-large wheels for ease of movement.

Features :

- The entire device conforms to IEC UL standard 60601-1.

- The recirculation function recycles surplus product water, lowering water use by up to 45%.

- RO is supplied cleaner water, which improves the unit’s quality and functionality.

- The plug-and-play controller facilitates programme updates and disinfection mode.

- The controller displays water quality values and warnings to keep you aware of operational circumstances.

If an alert is triggered, the system will stop the flow of product water to the patient. - Onboard disinfection is quick and simple with the press of a button.

- Even with cold water, a big membrane may feed two dialysis machines.

- The Nephros dual-stage ultra-filter captures microbiological pollutants as small as 0.005 microns.

- The test ports on the front cabinet make taking samples easier.

This product is completely customised, which means that we supply the capacity of the product based on the needs of the customer. We also supply all typical capacity plants.

How many effluent treatment plants are there in India?

according to the Central Pollution Control Board (CPCB), there were 3204 Common Effluent Treatment Plants (CETPs) and 2184 standalone effluent treatment plants (ETPs) operational in India as of March 2021. Please note that this number may have changed since then.

How much does an effluent treatment plant cost in India?

The cost of an effluent treatment plant (ETP) in India can vary depending on various factors such as the capacity of the plant, the type of treatment process required, the complexity of the design, and the materials used.

Generally, the cost of a small-scale ETP with a capacity of around 1000-5000 liters per day can range from Rs. 1 lakh to 5 lakhs (approximately $1,350 to $6,700 USD). Whereas, a medium-sized ETP with a capacity of around 50,000 liters per day can cost anywhere between Rs. 10 lakhs to 50 lakhs (approximately $13,500 to $67,000 USD).

It is important to note that these are just estimates, and the actual cost may vary depending on the specific requirements and conditions of the project. It is recommended to consult with ETP manufacturers or consultants to get a more accurate cost estimation for a particular project.

How many types of ETP plants are there?

There are several types of effluent treatment plants (ETPs) available, each designed for specific industrial and wastewater treatment requirements. Some of the common types of ETPs are:

Physicochemical Treatment Plants: These plants use chemical coagulants and flocculants to remove suspended solids, oil and grease, and heavy metals from wastewater.

Biological Treatment Plants: These plants use microorganisms to biodegrade organic pollutants in wastewater. The two main types of biological treatment plants are aerobic and anaerobic treatment plants.

Membrane Treatment Plants: These plants use a semi-permeable membrane to separate contaminants from wastewater.

Electrocoagulation Treatment Plants: These plants use an electrocoagulation process to remove contaminants from wastewater.

Reverse Osmosis Treatment Plants: These plants use a membrane filtration process to remove dissolved solids and contaminants from wastewater.

Evaporator Treatment Plants: These plants use an evaporator process to separate water from contaminants in wastewater.

The type of ETP chosen depends on the specific contaminants present in the wastewater, the treatment efficiency required, and the budget for the project.